GT-15 Drill Reamer

Modifications

REDUCED SHANK DIAMETER / FLAT

- To suit your operational requirements like chuck sizes and shapes.

SHORT TAPER / CUSTOM CUTTING ANGLE

- To suit specific applications where there is limited space to push through.

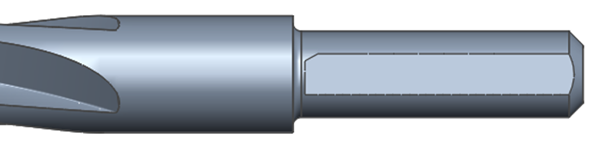

GT-15 Drill Reamer

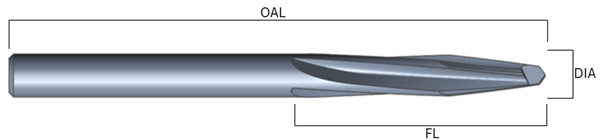

The GT-15 Drill Reamer is a high-performance carbide tool that combines drilling and reaming into a single operation for precision holemaking in composite and hybrid materials. Designed for efficiency and accuracy, it delivers extremely tight tolerances, clean finishes, and minimal material pushout — all in one step.

Available in 4-flute and 6-flute designs, the GT-15 is ideal for both manual and CNC operations across aerospace, automotive, and industrial applications.

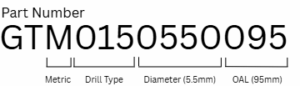

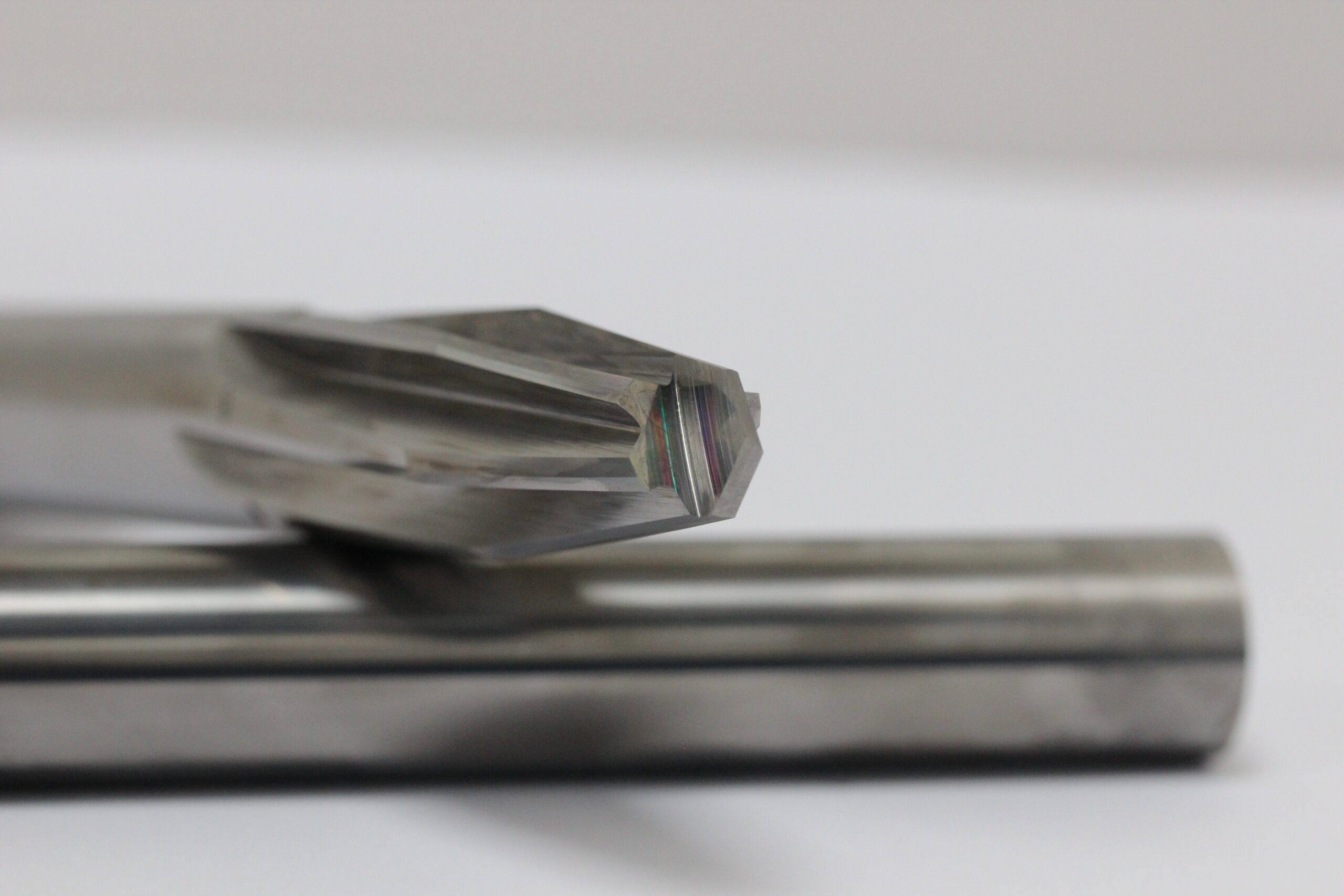

GT-15 Drill Reamer – 6 Flute

Key Benefits of the GT-15 Drill Reamer:

-

Drill and ream in a single operation

-

High-quality hole finish with minimal delamination or splintering

-

Tight tolerance and consistent diameter control

-

Long tool life and low cost per hole

-

Regrind service available

FOR BEST USE ON:

-

CARBON FIBRE

-

GLASS FIBRE

-

CARBON + ALUMINIUM STACK

- CARBON + TITANIUM STACK

-

GRAPHITE COMPOSITES

-

REINFORCED POLYMERS

- CERAMICS

SIZES AVAILABLE:

-

4-Flute: 2.4mm – 10.0mm (for smaller diameters)

-

6-Flute: 10.0mm+ (for larger diameters)

Intermediate sizes and tolerances upon request

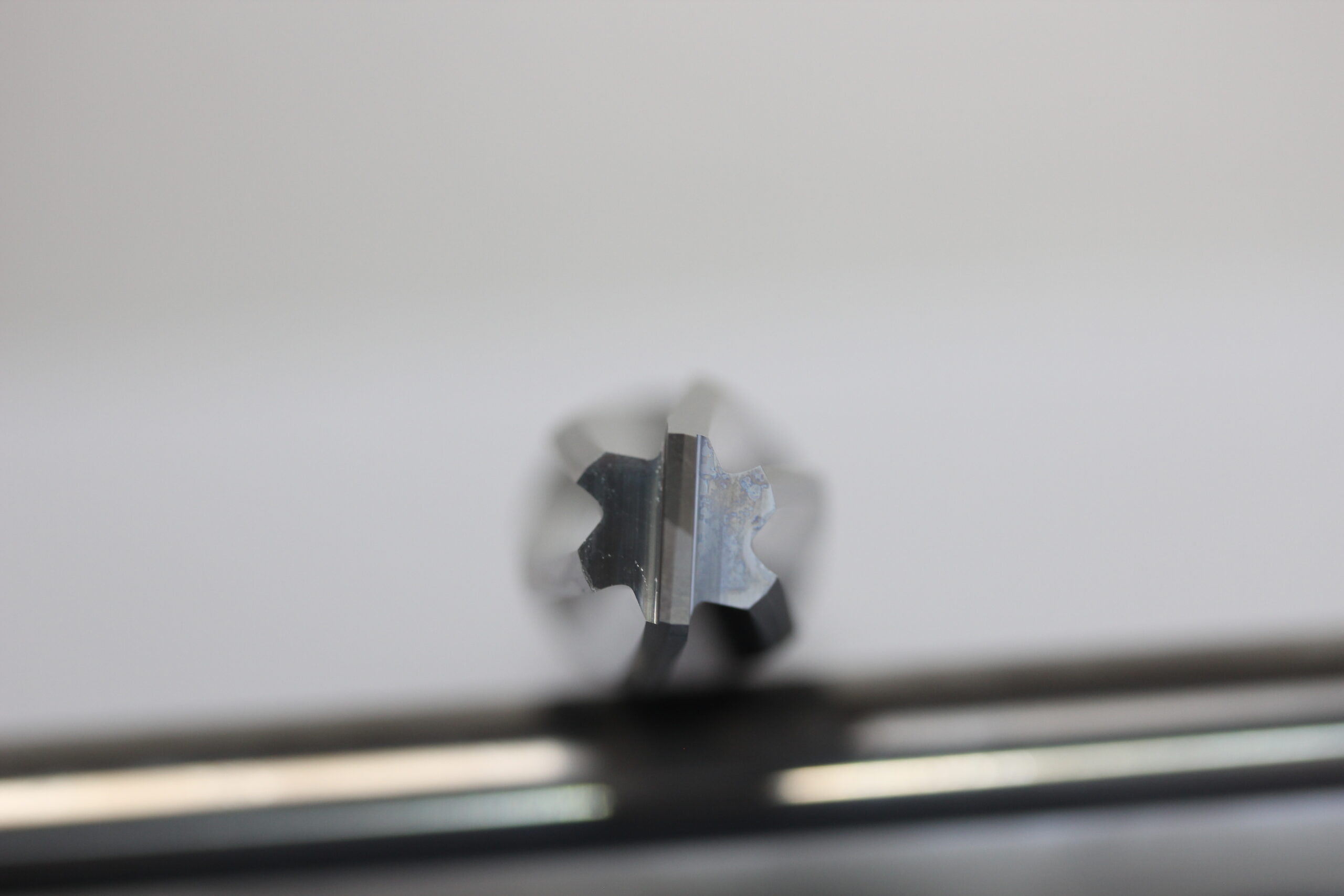

HOW DO OUR PART NUMBERS WORK?