GT-250 Kevlar Drill (W Point)

GT-250 Kevlar Drill (W Point)

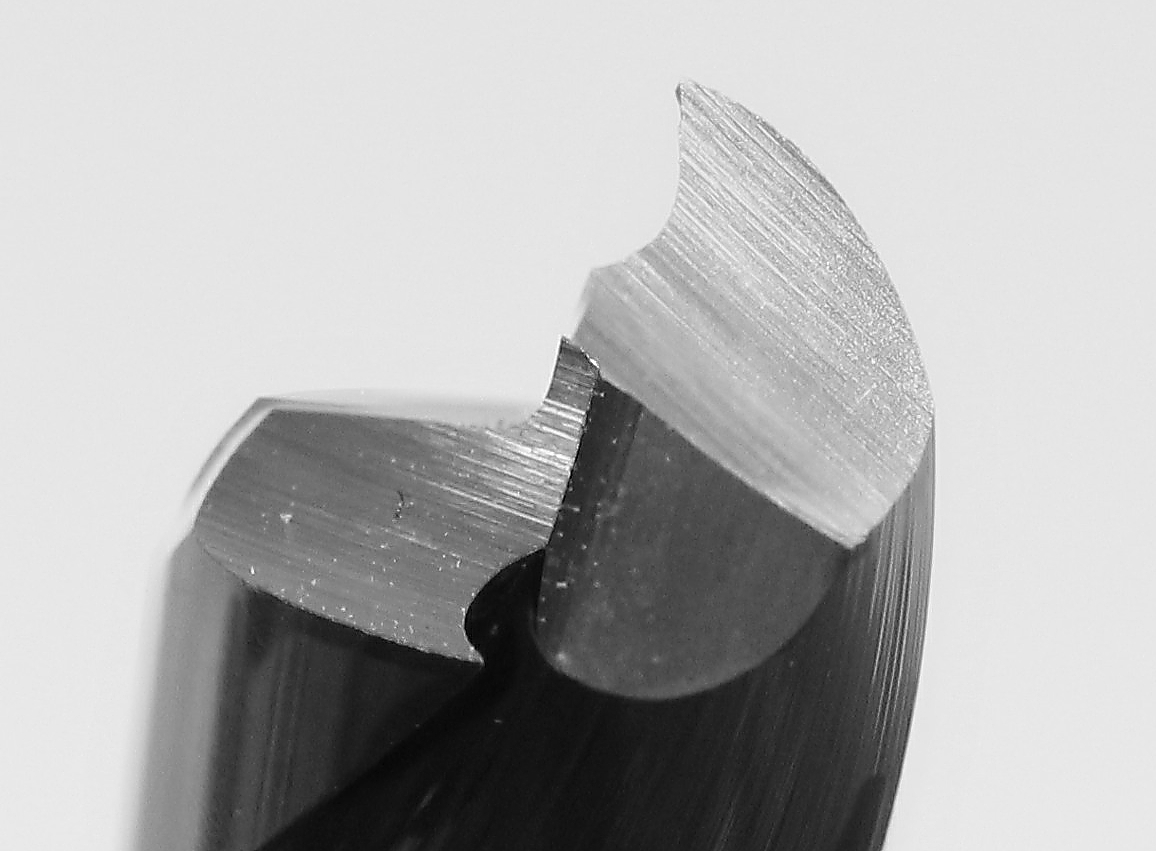

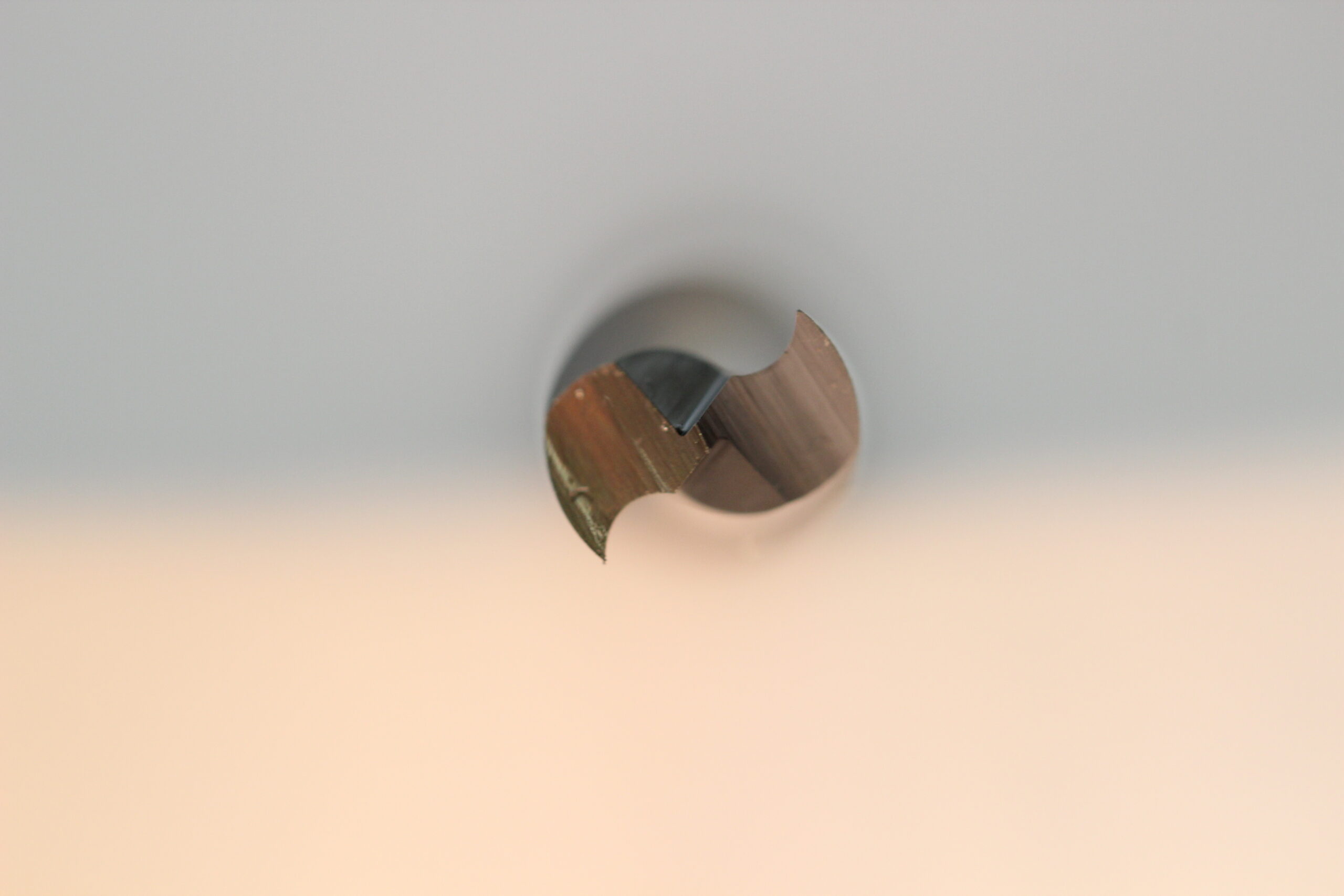

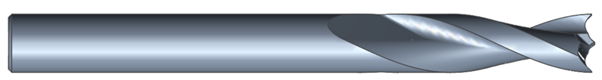

The GT-250 Solid Carbide Kevlar Drill is Gandtrack’s solution for drilling Kevlar and aramid composites, engineered with a unique W-Point cutting geometry. Rigorously tested across multiple Kevlar applications — including armour systems, pilotless drones, and ultra-light solar-powered aircraft — it consistently delivers clean holes with minimal fraying and no volcano effect.

With a proven track record in defence, aerospace, and advanced composites, the GT-250 offers smooth drilling and significant time savings in post-processing.

Key Benefits:

-

Fluff-free finish with minimal cleanup

-

No volcano effect — clean surface entry and exit

-

Operator-friendly and low-effort cutting

-

Two-flute design up to 12mm for balance and chip evacuation

-

New 3-flute version available for larger diameters

-

Tested and proven on real-world Kevlar products

FOR BEST USE ON:

-

KEVLAR

-

ARAMID FIBRES

-

BALLISTIC ARMOUR

-

CARBON COMPOSITES

- GLASS COMPOSITES

SIZES AVAILABLE:

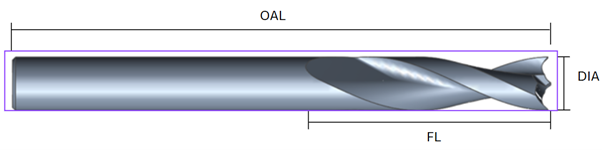

- 2-Flute: 2.4mm – 12.0mm (for smaller diameters)

- 3-Flute: 12.0mm+ (for larger diameters)

Intermediate sizes available upon request

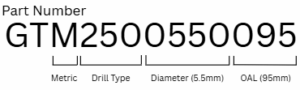

HOW DO OUR PART NUMBERS WORK?