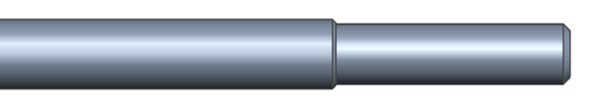

Carbide Tipped Drill

Carbide Tipped Drill

The Carbide Tipped Drill from Gandtrack combines the cutting performance of solid carbide with the flexibility and toughness of a high-speed steel (HSS) body. Designed for precision drilling in composites and metals, this hybrid construction is ideal for small diameters or extended reach applications, where solid carbide tools may be too brittle.

The carbide tip ensures excellent abrasion resistance and clean hole finishes, while the HSS body absorbs more flex and reduces the risk of breakage. Suitable for use through a drill bush, making it ideal for guided drilling setups in aerospace and precision manufacturing.

Key Benefits of Carbide Tipped Drills

-

Carbide Tip Cutting Edge: Delivers high wear resistance and sharp cutting action.

-

HSS Body: Offers greater flexibility and reduced breakage risk on long or small-diameter tools.

-

Ideal for Guided Drilling: Suitable for bush-guided setups and fixtures.

-

Versatile Performance: Suitable for composite stacks, metals, and hybrid materials.

-

Available Upon Request: Custom sizes and lengths tailored to your application.

For Best Use On

-

Carbon Fibre & Composites

-

Aluminium & Aerospace Alloys

-

Carbon + Aluminium or Titanium Stacks

-

Graphite and Reinforced Polymers

SIZES AVAILABLE:

- From 2mm – 17.0mm +

Intermediate sizes and tolerances upon request