GT-12 Left Hand Helix Drill

GT-12 Left Hand Helix Drill

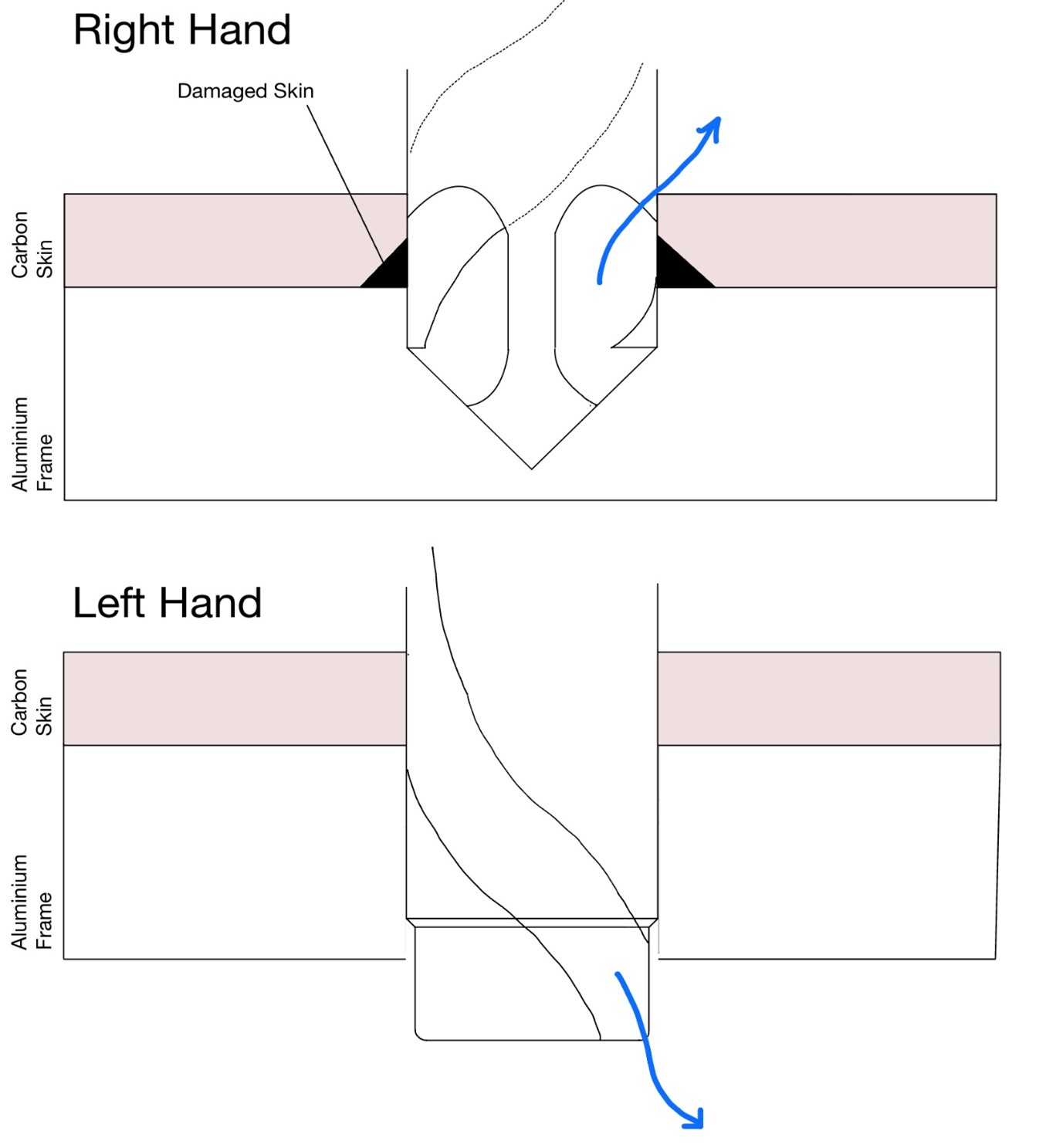

The GT-12 Left Hand Helix Drill by Gandtrack is a high-performance solid carbide drill specifically engineered for non-bonded carbon and aluminium stacks. Featuring a right-hand cutting direction with a left hand helix, this advanced geometry pushes swarf forward through the pilot hole – protecting the inner surface of carbon fibre layers from damage, delamination, or scoring during exit.

Perfect for aerospace composite drilling, this drill ensures clean hole finishes, controlled chip flow, and long tool life in demanding materials.

Key Benefits of the GT-12 Left Hand Helix

-

Left Hand Helix Geometry: Directs swarf away from the carbon layer to avoid internal damage.

-

Right Hand Cutting: Compatible with conventional spindle rotation and CNC programs.

-

Optimized for Stack Drilling: Ideal for hybrid materials like carbon + aluminium or carbon + titanium.

-

Clean Finishes: Reduces fibre breakout and delamination in composite materials.

For Best Use On

-

Carbon + Aluminium Stacks (non-bonded)

-

Carbon Fibre and Graphite Composites

-

Hybrid Aerospace Materials

-

Reinforced Polymers with Metallic Backing

SIZES AVAILABLE:

- From 2.5mm – 20.0mm +

Intermediate sizes and tolerances upon request