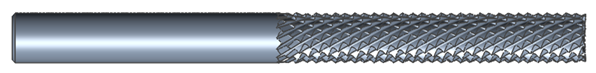

GT-14 Cross Cut Router

Modifications

REDUCED SHANK DIAMETER

- To suit your operational requirements like chuck sizes.

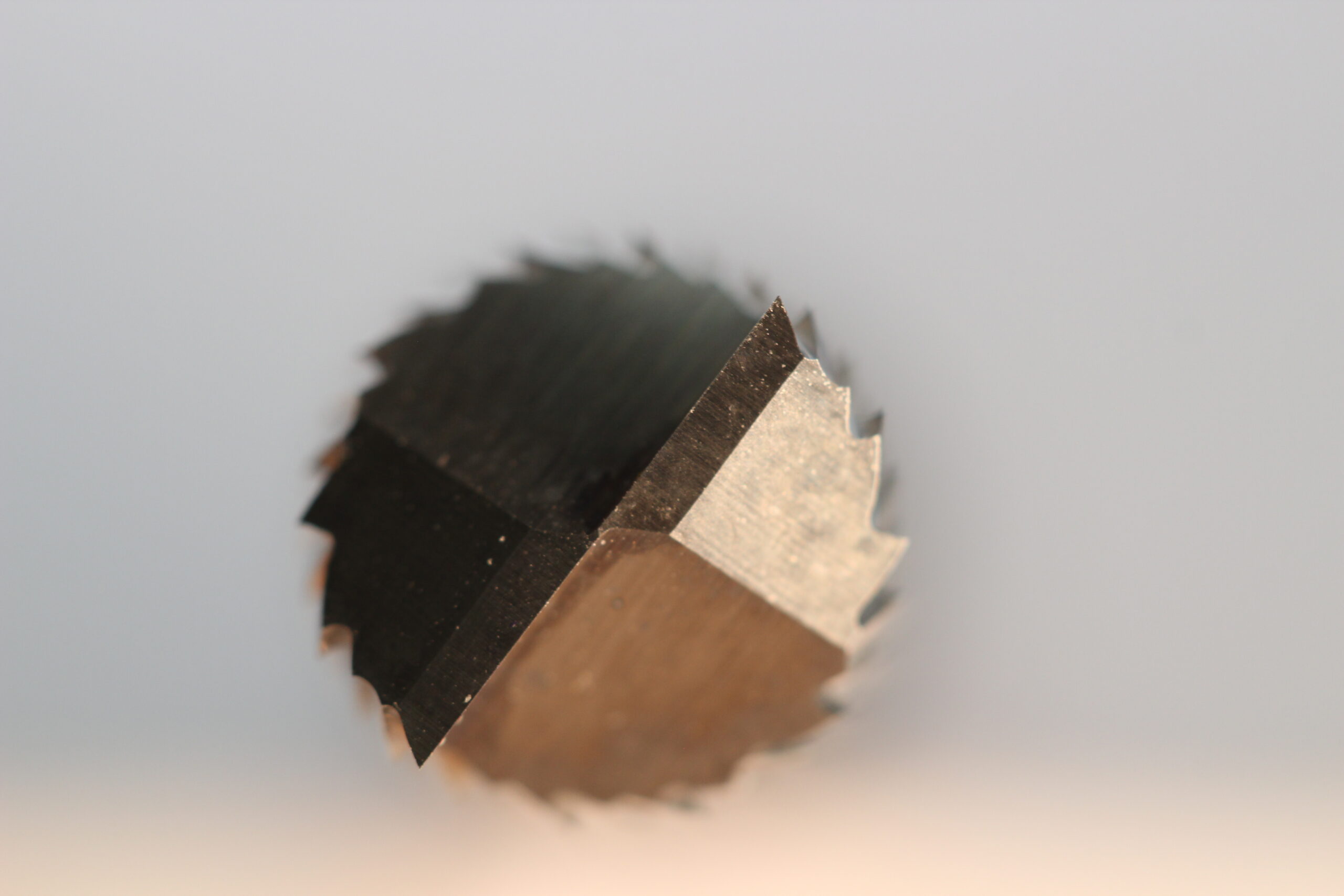

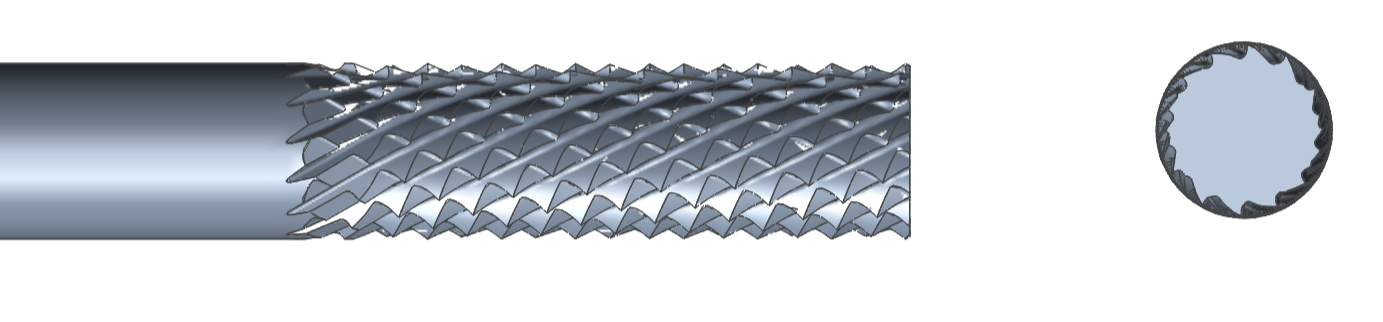

FLAT END – surface clean up and straight wall cuts, profile applications.

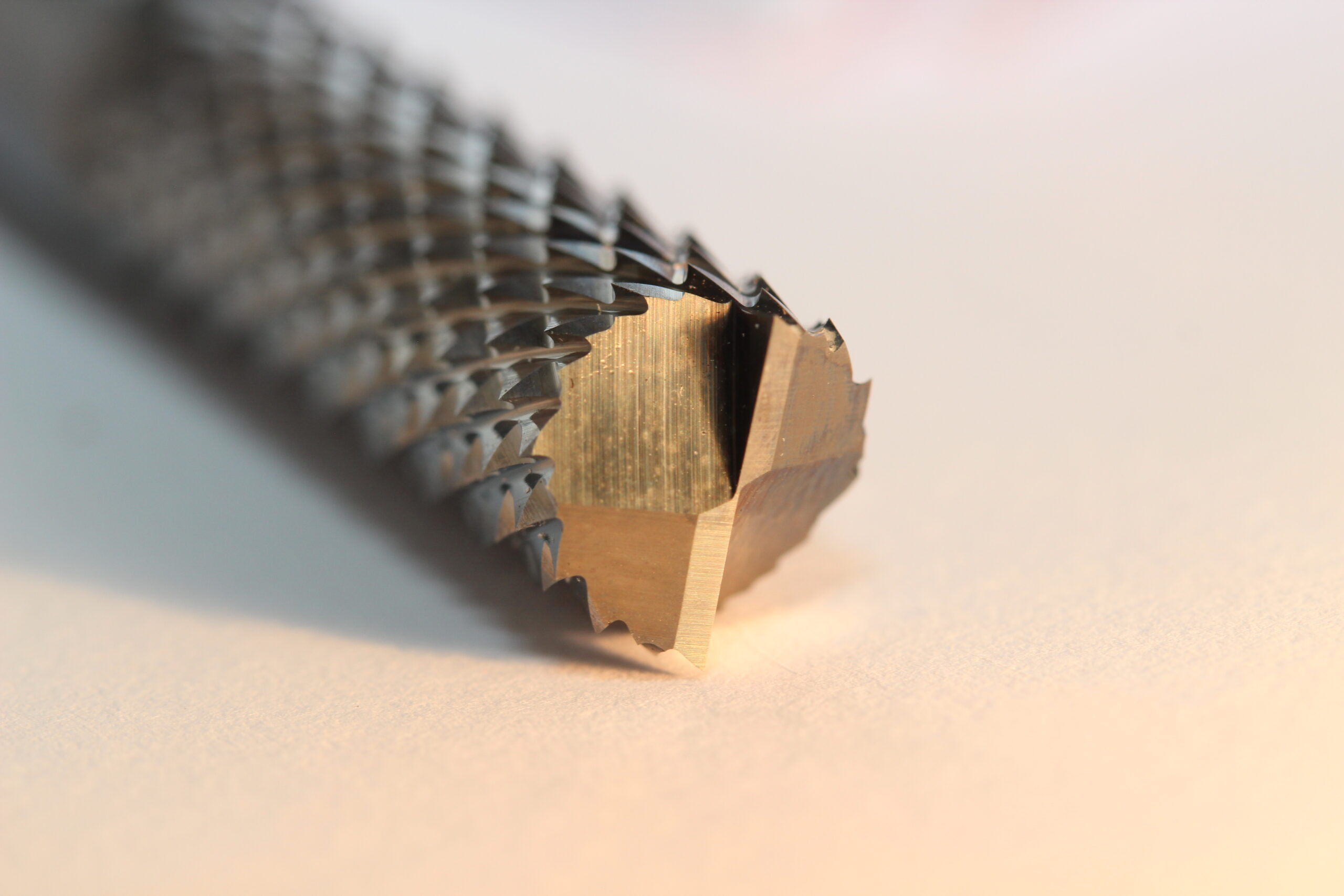

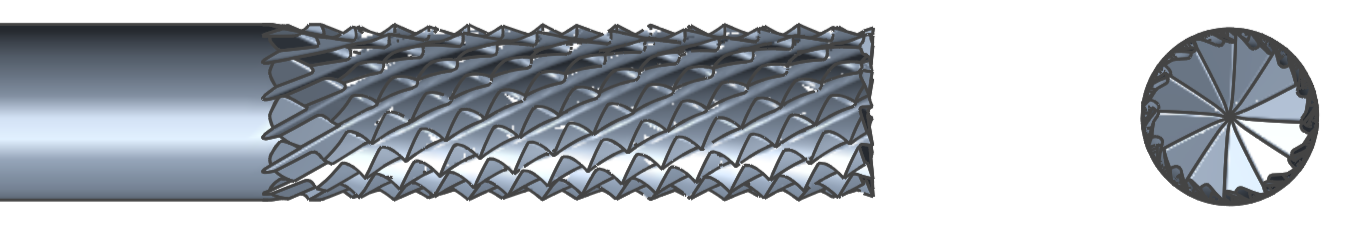

BURR END – Aggressive material removal and edge finishing, profile and slotting applications.

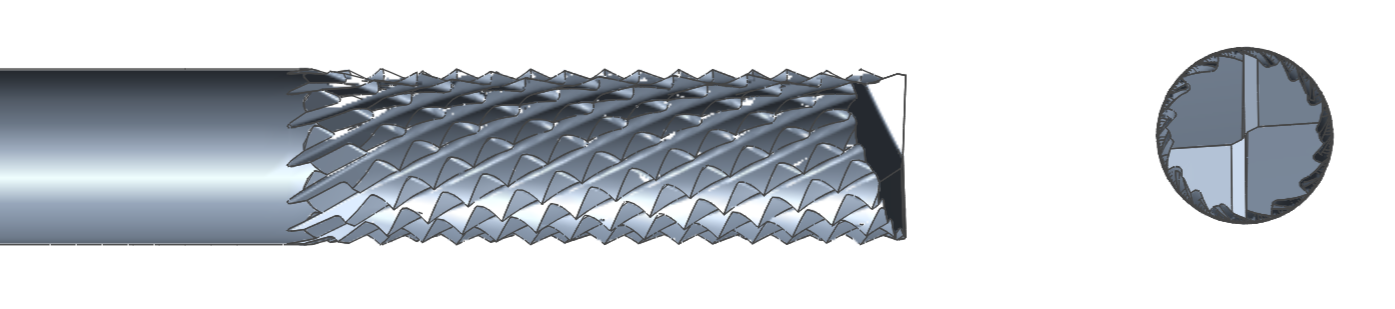

END CUT (SLOT DRILL / MASTERMILL) – For plunge cutting and slotting, square corner.

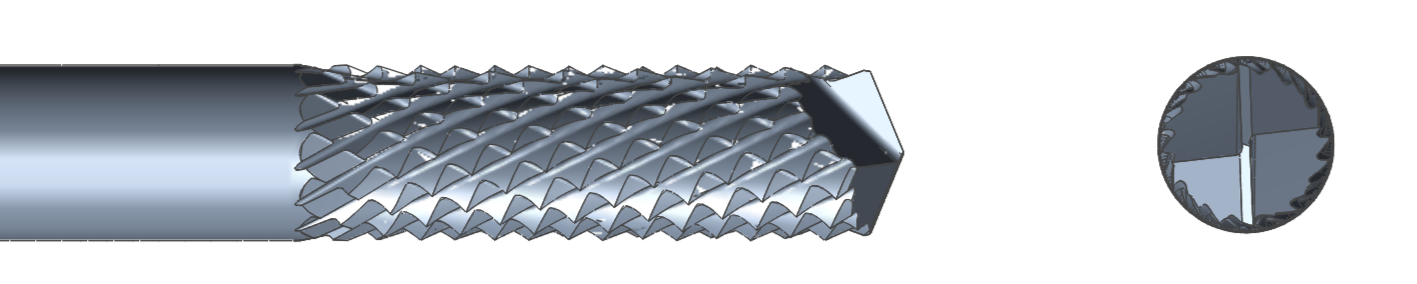

DRILL POINT – accurate drilling or pilot hole creation in composites, before routing.

GT-14 Cross Cut Router

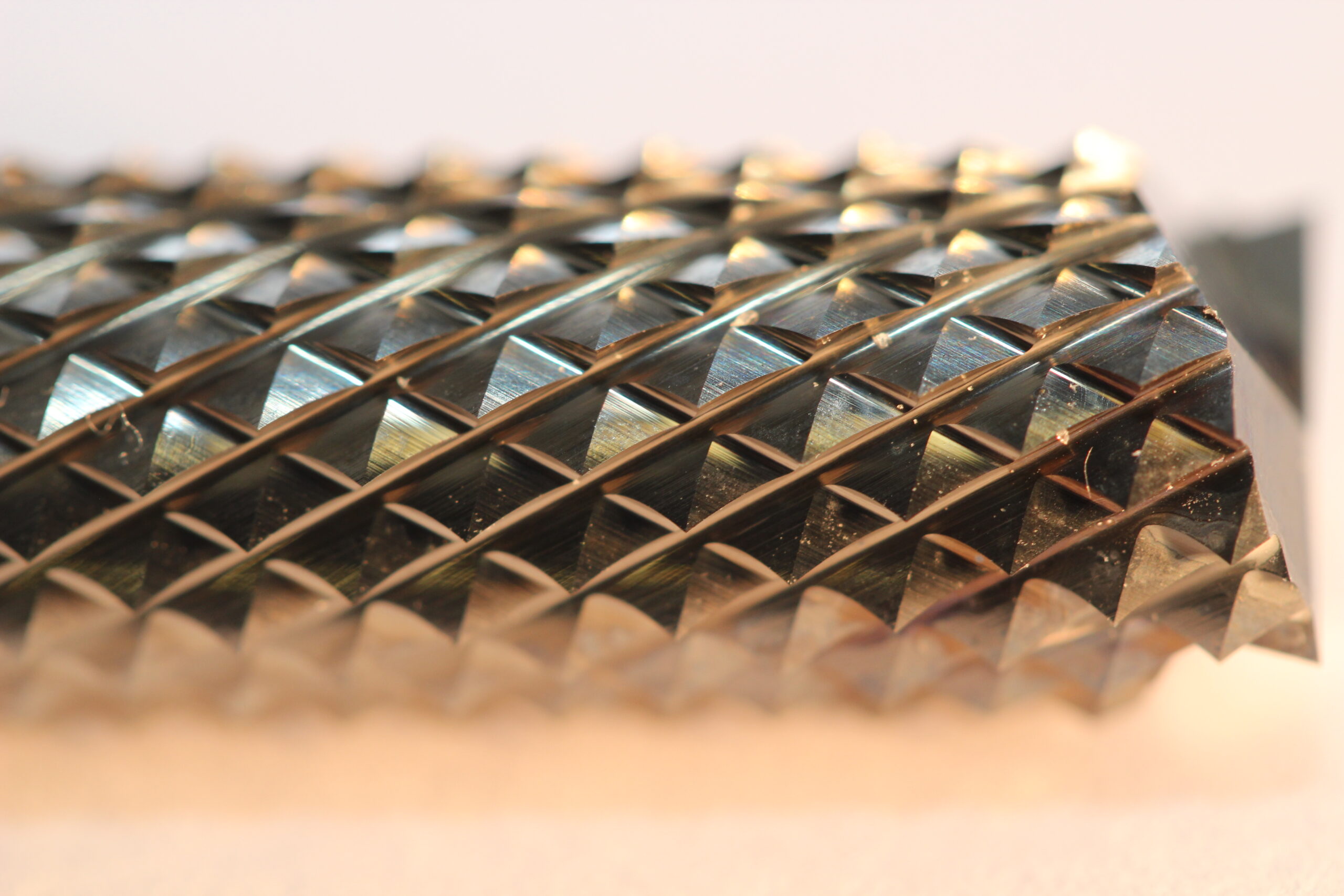

The GT-14 Diamond Cut Router is a solid carbide, high-performance rotary tool designed for aggressive cutting, trimming, and edge profiling in carbon fibre, glass fibre, and other reinforced composites. With a diamond-cut flute pattern and a choice of specialized end geometries, it offers maximum cutting versatility across both manual and CNC applications.

Whether you need plunge cutting, slotting, profiling, or surface preparation, the GT-14 provides exceptional control, high abrasion resistance, and long tool life even in the most demanding composite environments.

Key Benefits:

-

Diamond-cut flutes reduce tool loading and cut aggressively without fraying

-

Multiple end geometries tailored to different operations and material types

-

Solid carbide body ensures durability in abrasive composite materials

-

Excellent edge quality with minimal delamination or breakout

-

Compatible with CNC routers and manual tools

FOR BEST USE ON:

-

Carbon Fibre / CFRP (DLC coatings available)

-

Glass Fibre / GFRP

-

Reinforced Polymers & Thermoplastics

-

Graphite Composites

-

Carbon and Aluminium Hybrid Stacks

SIZES AVAILABLE:

- From 1.6mm – 12mm +

Intermediate sizes and tolerances upon request

Not available for Gandtrack’s regrind service.