GT-38 Radius Point Drill

GT-38 Radius Point Drill

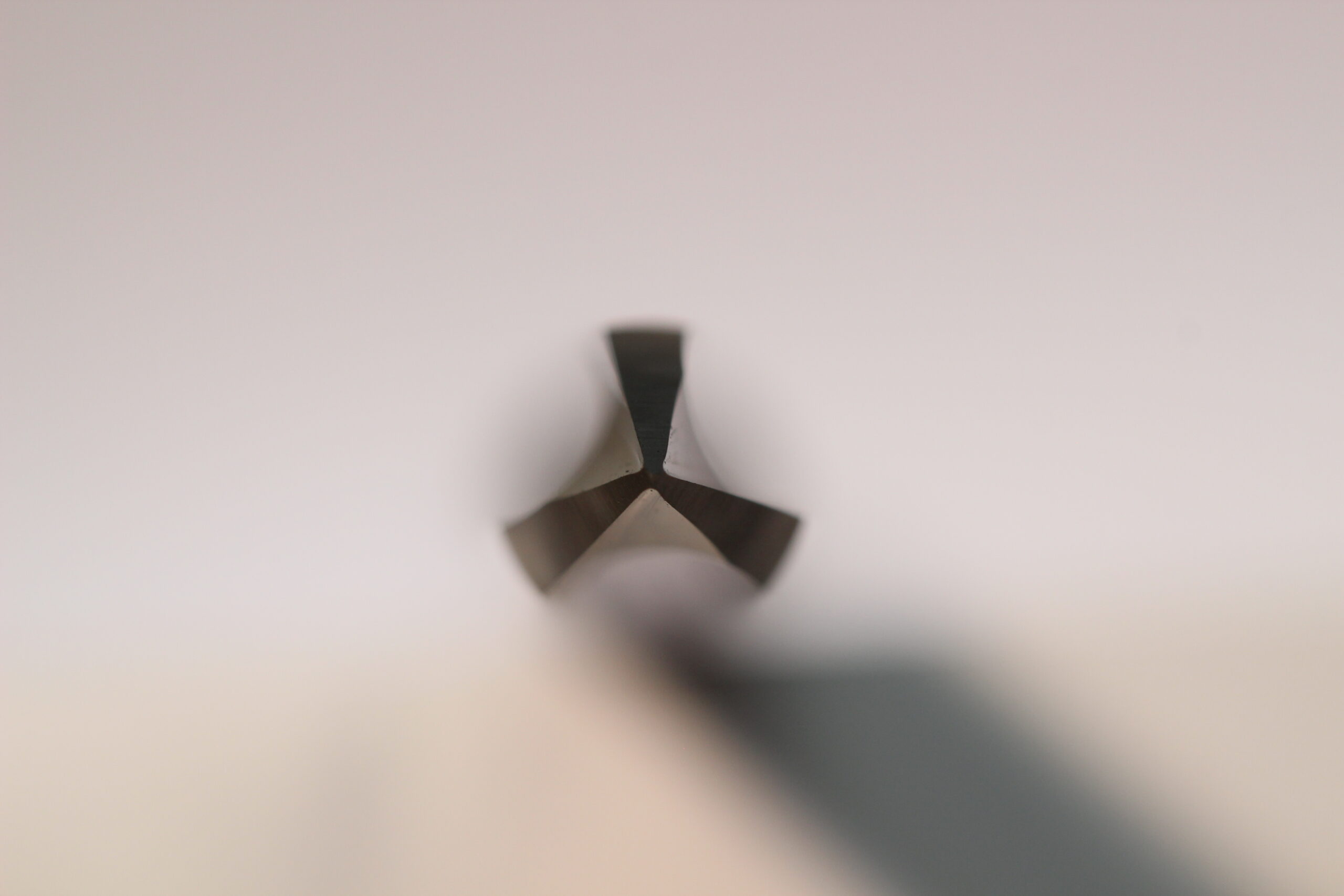

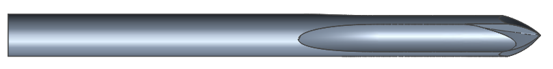

The Solid Carbide GT-38 Radius Point Drill is engineered for manual and low-speed drilling in abrasive composite materials such as carbon fibre, glass fibre, and hybrid laminates. Designed with a radius point geometry, it provides smooth entry, reduces delamination, and maintains hole quality — even when drilling from solid.

Its rounded design helps distribute cutting forces more evenly, lowering the risk of material breakout or edge chipping, which is particularly critical when working on finished parts or thin laminates. Whether you’re opening holes or drilling from solid, the GT-38 ensures precision, durability, and operator control.

Key Benefits of the Radius Point Drill:

-

Radius point geometry for reduced delamination and cleaner entry

-

Capable of drilling from solid with minimal pushout

-

Ideal for hand drilling and low-RPM operations

-

High abrasion resistance for use in tough composites

-

Excellent heat resistance — maintains sharpness during manual use

FOR BEST USE ON:

-

CARBON FIBRE / CFRP

-

GLASS FIBRE / GFRP

-

REINFORCED POLYMERS & COMPOSITES

-

HYBRID STACKS (Carbon + Aluminium)

SIZES AVAILABLE:

-

From 2.5mm – 12.0mm

Intermediate sizes and tolerances upon request

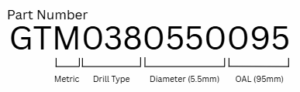

HOW DO OUR PART NUMBERS WORK?