GT-16 Two Flute Drill

Modifications

REDUCED SHANK DIAMETER

- To suit your operational requirements like chuck sizes.

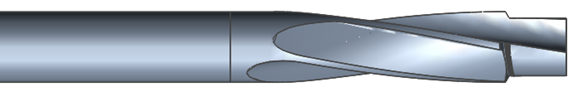

STEPPED PILOT – CUTTING

- To drill holes from solid and open up in steps.

STEPPED PILOT – NON-CUTTING

- To open up existing holes in steps.

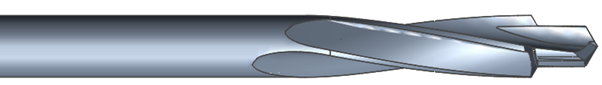

GT-16 Two Flute Drill

The GT-16 Two Flute Drill Solid Carbide Drill is engineered for precision drilling in composite materials such as carbon fibre, GFRP, and hybrid stacks including carbon/aluminium and carbon/titanium. Designed for both manual and CNC use, the GT-16 provides delamination-free performance, clean hole finishes, and superior chip evacuation thanks to its refined flute geometry.

Key Features & Benefits:

- Two Flute Drill Design for smooth, chatter-free drilling and fast chip clearance

- Optimized Cutting Edges reduce delamination and fibre breakout

- Solid Carbide Construction for long life, heat resistance, and clean hole quality

- Versatile Use across composite stacks in aerospace, automotive, and industrial applications

For Best use on:

- Carbon Fibre / CFRP

- Carbon + Aluminium Stacks

- Carbon + Titanium Stacks

- Glass Fibre / GFRP

- Graphite Composites & Reinforced Polymers