history OF GANDTRACK

1979

The British Aerospace EAP

The British Aerospace EAP (for Experimental Aircraft Program) was a British technology demonstrator aircraft developed as a private venture in the 1980s and which eventually formed the basis for the Eurofighter Typhoon. Only one EAP was ever built and carried the registration serial number of ZF534

1981

Gandtrack Ltd. is incorporated

Gandtrack Ltd, situated in Hoyland Common in Barnsley, was incorporated by Harry Jackson (left) and Brian Hirst (right) to work on the development of the EAP, with the aim to provide composite cutting tool solutions

1988

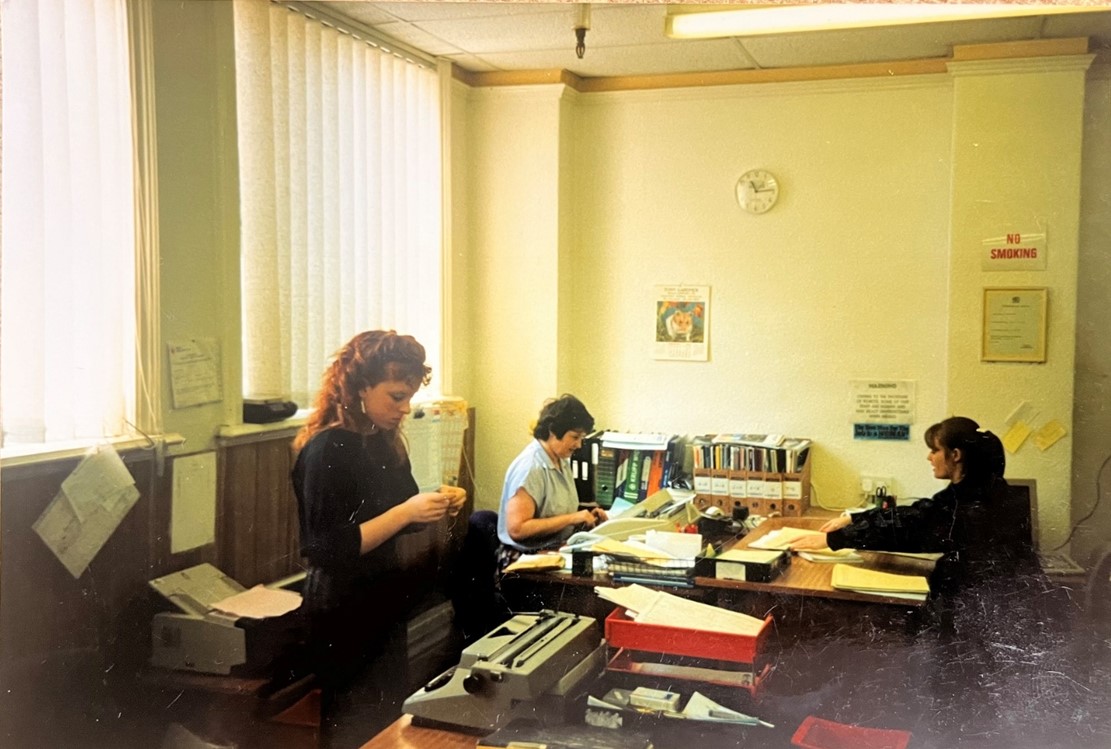

Gandtrack moves office

Gandtrack moved into a new office space in Wellington Mill, Chew Valley road Greenfield.

1996

Gandtrack moves premises

Gandtrack moved into a new office and warehouse space in Thamewater Mill, Delph New Road, Dobcross, to facilitate the option to expand as the product list that Gandtrack were supplying grew.

2000

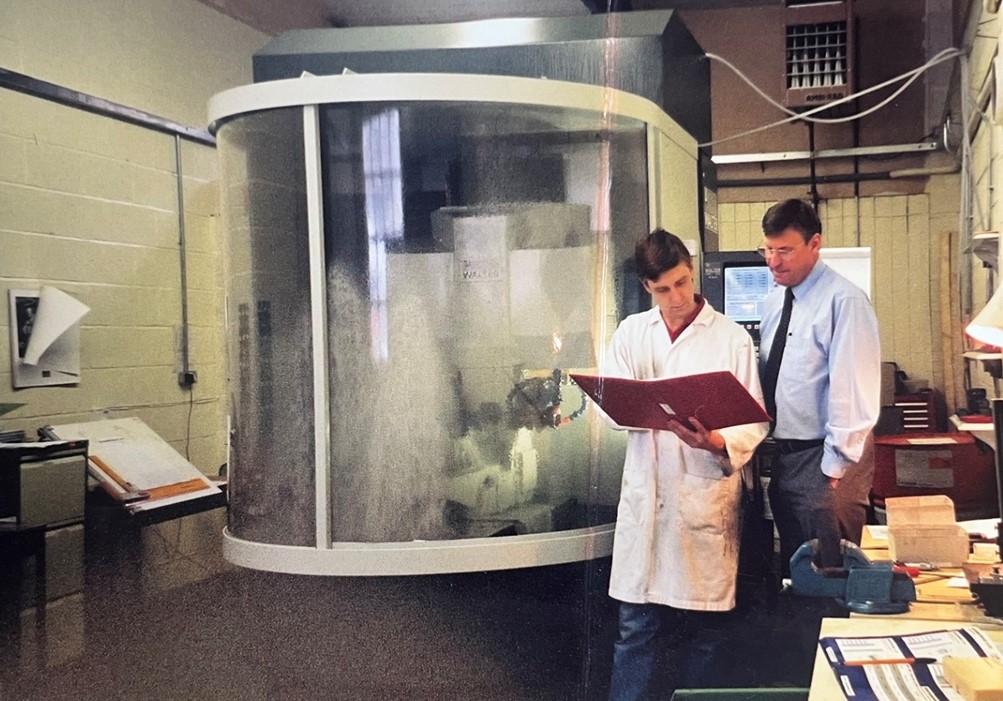

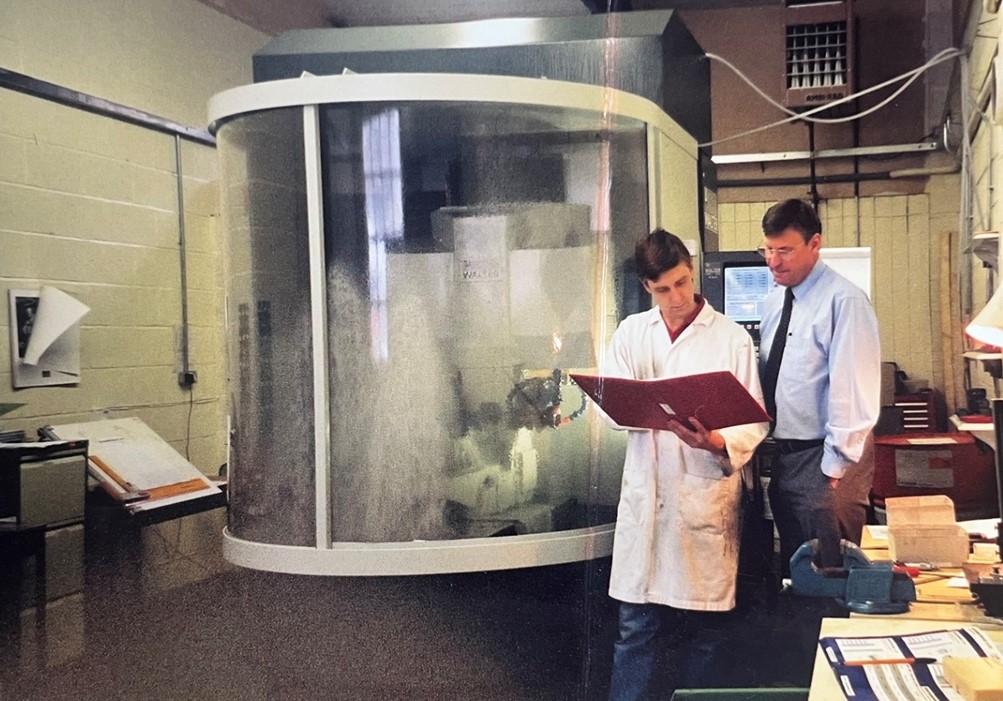

First Walter Machine

After trading Carbide tips for over 15 years, Gandtrack acquired their first CNC Grinding machine, the Walter Helitronic Power, to expand the business into the manufacturing industry.

2000

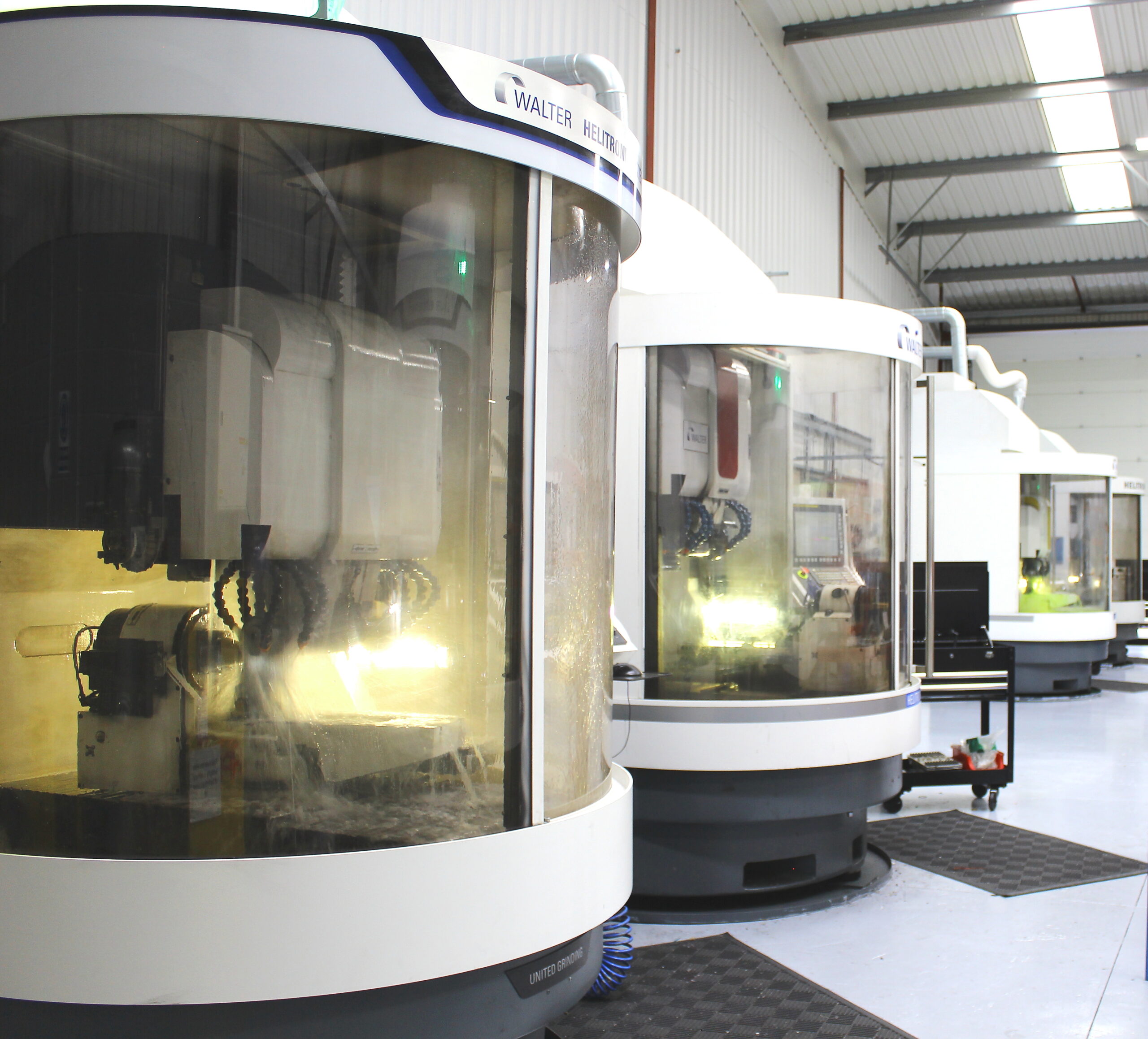

CNC Walter Machines

Expansion of manufacturing with the addition of our second Walter machine, closely followed by the third to due rapid growth plans.

2005

Gandtrack move to new premises

To house an expanding inventory of machines and workforce, Gandtrack move into nearby town, Oldham. This is where you will find Gandtrack’s offices today.

2008

Gandtrack’s first tool management system is installed at Safran Nacelles

Gandtrack’s vending machine system revolutionised Safran’s tool management by providing comprehensive visibility and control over their inventory. This would be the first of five machines at their site in Burnley.

2008

Gandtrack Asia Sdn Bhd

Gandtrack’s sister company, Gandtrack Asia Sdn Bhd was set up in 2008 to support customers in Malaysia and across Asia with their cutting tool needs, namely Spirit and Boeing.

2011

Gandtrack Asia Walter CNC Machine

Due to increased workload from Gandtrack Asia, we send one of our

CNC machines to support the regrind service, a replacement for our UK

factory is ordered.

2012

Replacement CNC Machine

Gandtrack take delivery of the replacement machine, expanding our inventory to 4 CNC machines.

2013

Walter Helicheck Inspection

The first Walter Helicheck, ‘Advanced’, is acquired, giving Gandtrack 100% control over the quality inspection of all tools.

2014

Another new Walter machine is purchased, this time replacing our first machine which was refurbished and relocated to our sister company GT Grinding. This was our first CNC machine with automated loading capability meaning for the first time in our history we had lights out running.

2018

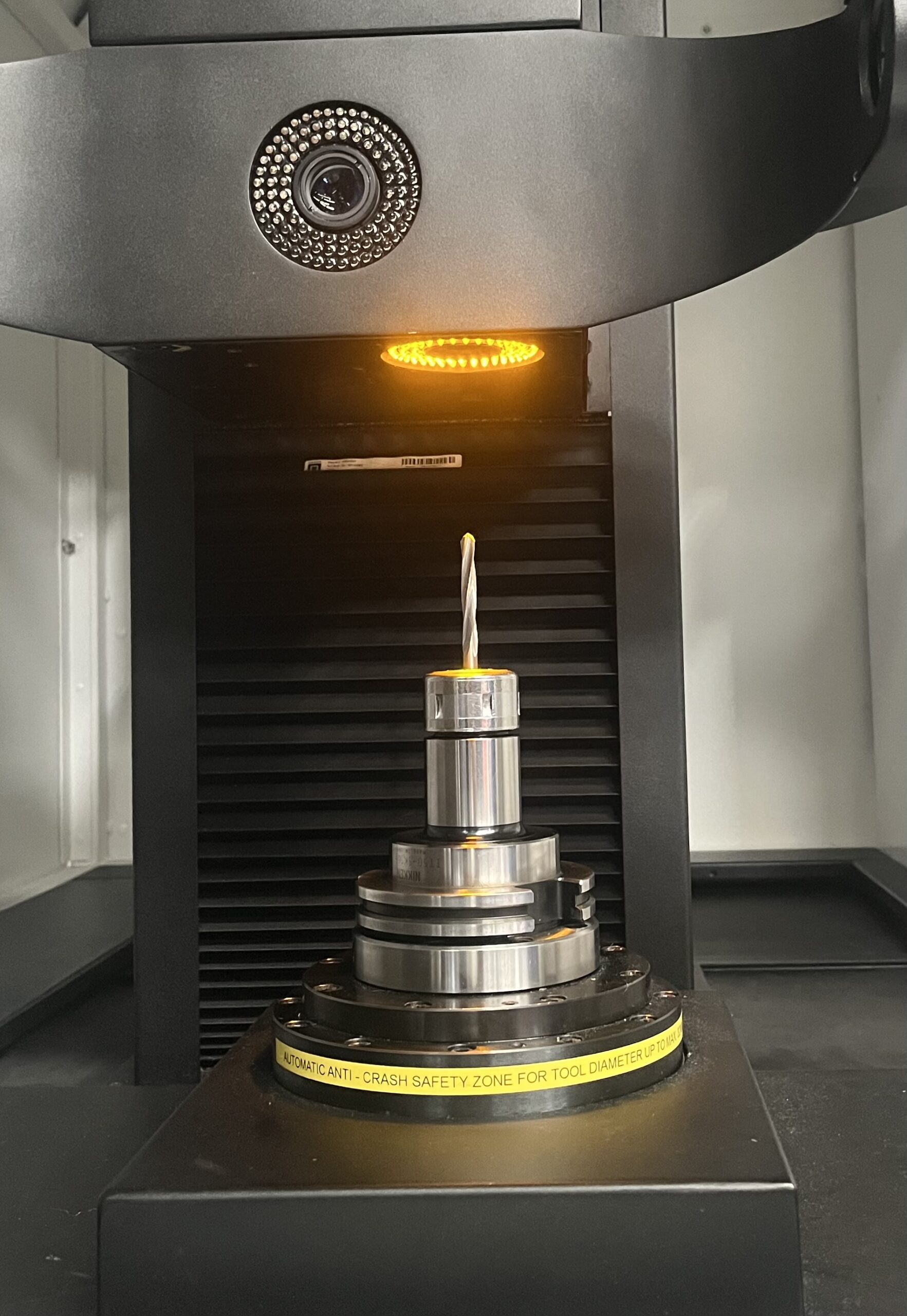

Walter Helicheck 3D

After a successful open day in Germany at Walter Machines HQ, we purchased the UK’s first 3d Inspection machine which has helped develop the latest in advanced cutting tool technologies.

2019

Walter Helitronic Power

The company’s biggest investment in machinery to date saw the introduction of a new Walter CNC Grinding machine with a Fanuc robot loader and automated tailstock. Meaning we now have the capacity to run the machine lights out for longer periods with the large pallet system. The increased capacity has led to us being able to maintain demand from our customers large stock requirements

2024

Distributors for Cleveland

Appointed UK distributor for Cleveland drills opening new customers and markets previously unavailable to the company.

With 10 members of staff, we are on target for increased year on year sales, the future is looking promising with the support of all our team.