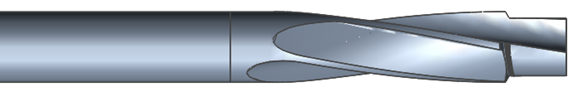

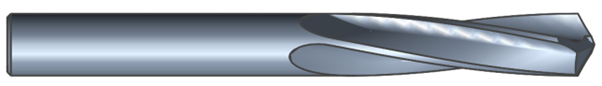

GT-105 Burnishing Drill

Modifications

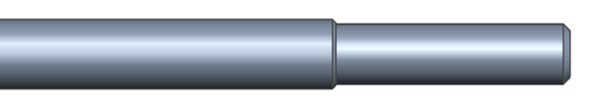

REDUCED SHANK DIAMETER

- To suit your operational requirements like chuck sizes.

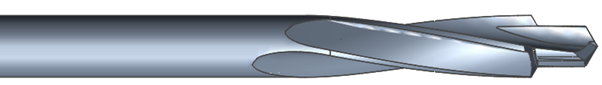

STEPPED PILOT – CUTTING

- To drill holes from solid and open up in steps.

STEPPED PILOT – NON-CUTTING

- To open up existing holes in steps.

GT-105 Burnishing Drill

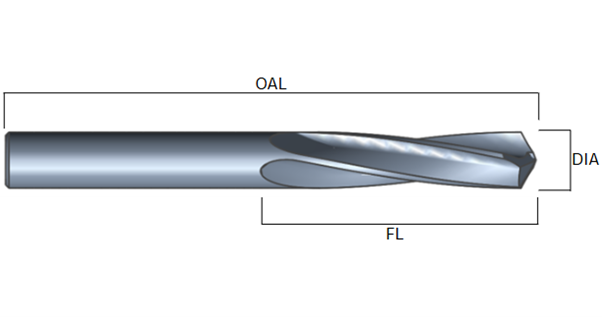

The GT-105 Burnishing Drill is a precision carbide tool that combines drilling, sizing, and surface burnishing in a single-pass operation. Engineered for high-performance hole quality, it delivers tight tolerances, exceptional roundness, and a smooth, high-grade surface finish - all without the need for secondary operations.

Designed with a double-margin and 4-land burnishing geometry, the GT-105 provides enhanced stability, reduces vibration, and ensures consistent, clean hole finishes with every pass.

Key Benefits:

-

One-pass drilling, sizing, and burnishing

-

Double-margin design for superior stability and precision

-

4-land geometry for smooth, chatter-free hole finishing

-

No need for reaming or polishing

-

Produces consistently high-quality surface finishes

FOR BEST USE ON:

- CARBON

- CARBON + ALUMINIUM STACK

- CARBON + TITANIUM STACK

SIZES AVAILABLE:

- From 2.5mm - 20.0mm +

Intermediate sizes and tolerances upon request

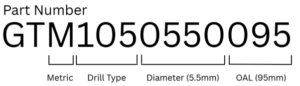

HOW DO OUR PART NUMBERS WORK?