GT-12 Para Flute Drill

Modifications

REDUCED SHANK DIAMETER

- To suit your operational requirements like chuck sizes.

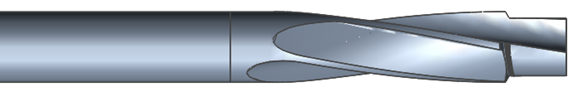

STEPPED PILOT – CUTTING

- To drill holes from solid and open up in steps.

STEPPED PILOT – NON-CUTTING

- To open up existing holes in steps.

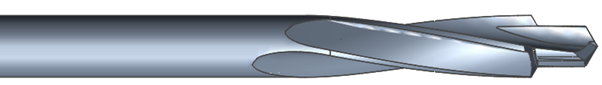

GT-12 Para Flute Drill

The GT-12 Para Flute Drill is a versatile solid carbide tool coated with AlTiN (TiAlN) designed for clean, accurate drilling in composite materials and aerospace-grade alloys. Its optimised flute geometry ensures fast chip evacuation, low delamination, and strong performance in both manual and CNC operations. The GT-12 was developed as a more aggressive version of the GT-16, including specialized coating to ensure longer lifespan and cleaner holes. It offers increased feed rates, longer tool life, and cleaner holes in tougher or more abrasive composite stacks.

Key Benefits of the Para Flute Drill:

- 2-Flute Design for smooth drilling and effective chip clearance

- Aggressive geometries like sharper cutting angle, helix angle and rake angles changed to cut faster through tougher materials.

- Parabolic fluting improves chip evacuation and reduces cutting forces.

- AlTiN coating provides excellent performance at high temperatures and speeds, making it ideal for tough materials and high-precision applications.

- Solid Carbide Build offers long tool life and heat resistance

- Versatile Use in hand or CNC machines across composite applications

FOR BEST USE ON:

- CARBON

- CARBON + ALUMINIUM STACK

- CARBON + TITANIUM STACK

- GLASS FIBRE

- GRAPHITE COMPOSITES AND REINFORCED POLYMERS