GT-50 Dagger Drill

Modifications

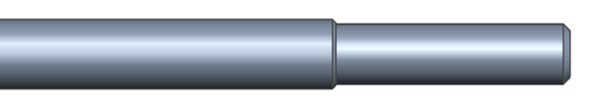

REDUCED SHANK DIAMETER

- To suit your operational requirements like chuck sizes.

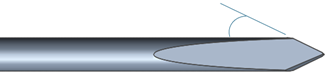

CUTTING ANGLE

- For preference on cutting geometry (not often recommended)

GT-50 Dagger Drill

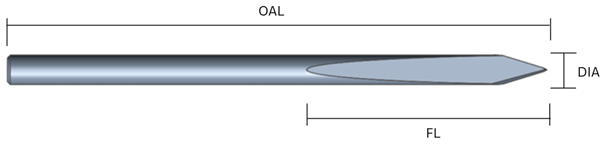

The GT-50 Solid Carbide Dagger Drill is one of Gandtrack’s flagship solutions for high-precision composite drilling. Engineered with a specialised point geometry, it reduces cutting forces at the centre, minimizing pushout, and delivering clean, accurate holes — all while preventing delamination and splintering.

Designed for both manual drilling and CNC operations, the GT-50 offers outstanding performance across demanding industries where precision and reliability are critical.

Key Benefits of the Dagger Drill:

-

Delamination-free drilling in layered composite materials

-

Reduced cutting forces for stable, accurate holemaking

-

Clean exit with minimal pushout or burrs

-

Suitable for both hand and CNC operations – guaranteed precision

-

Operator-friendly with consistent performance and confidence

-

Cost-effective due to fast cycle times and extended tool life

FOR BEST USE ON:

-

CARBON FIBRE / CFRP

-

GLASS FIBRE / GFRP

-

GRAPHITE COMPOSITES

-

PLASTIC COMPOSITES

SIZES AVAILABLE:

- From 1mm – 20mm +

Intermediate sizes and tolerances available

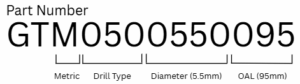

HOW DO OUR PART NUMBERS WORK?