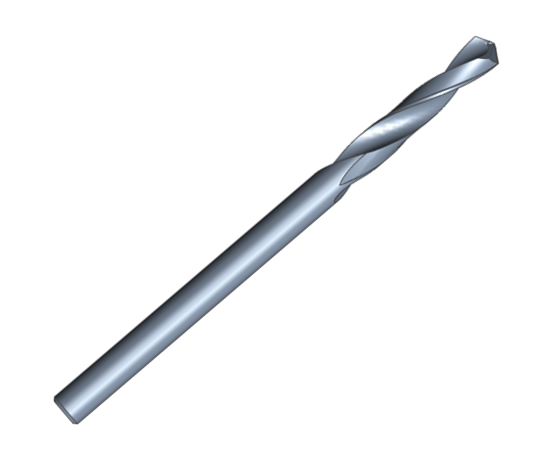

Taper Web Drill

Taper Web Drill

The Gandtrack Taper Web Drill is a solid carbide drill designed for increased strength, rigidity, and precision when drilling into composite materials and hybrid stacks. With a gradually thickening web (core) from pilot to shank, the taper web geometry provides enhanced tool stability, making it ideal for high-accuracy drilling with reduced deflection and longer tool life. As the web thickens toward the shank, the drill can handle more torque without twisting or breaking – the web acts like a strong spine in the drill. It helps resist bending and torsional (twisting) forces that act on the drill as it rotates and cuts through material.

In deep holes or hard materials, the tip of a regular drill (with a thin, constant web) might deflect or snap, but a taper web drill has progressive reinforcement behind the point, reducing the chance of failure.

Reliable performance in both manual and CNC operations, particularly when drilling abrasive materials like carbon fibre, glass fibre, and carbon/aluminium stacks.

Key Benefits of Gandtrack’s Taper Web Drill

- Tapered Web Geometry: Strengthens the tool core for reduced breakage and greater stability.

- Precision Hole Quality: Ideal for composite materials prone to delamination or splintering.

- Reduced Deflection: Provides improved hole straightness in deep or thin-wall components.

- CNC & Manual Compatibility: Performs reliably across both automated and manual setups.

For Best Use On

- Carbon Fibre

- Glass Fibre (GFRP)

- Carbon + Aluminium Stacks

- Graphite and Reinforced Polymers

- Aerospace Composites

- Thin-Wall or Deep Hole Applications

SIZES AVAILABLE:

- From 2.5mm – 20.0mm +

Intermediate sizes and tolerances upon request