GT-39 Tri Flute Drill

Modifications

REDUCED SHANK DIAMETER

- To suit your operational requirements like chuck sizes.

STEPPED PILOT – CUTTING

- To drill holes from solid and open up in steps.

STEPPED PILOT – NON-CUTTING

- To open up existing holes in steps.

BESPOKE GEOMETRIES

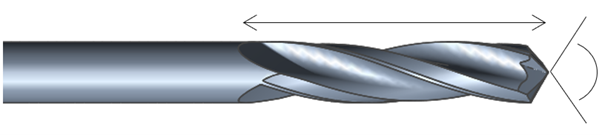

GT-39 Tri Flute Drill

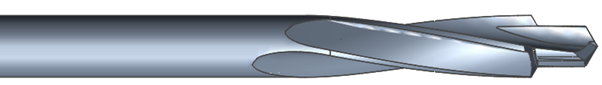

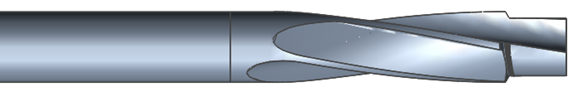

The GT-39 Tri Flute Drill is a high-performance solid carbide tool engineered for precision drilling in advanced composite materials. Designed with three cutting edges and three lands, the GT-39 offers enhanced hole size control, superior surface finish, and excellent guiding stability – even under heavy feed rates. Its thicker web increases strength and durability, making it ideal for demanding drilling operations where precision and tool life are critical.

Whether used in manual or CNC machining, the GT-39 ensures reliable, clean results in carbon fibre, glass fibre, and reinforced polymers.

Key Benefits of the Tri Flute Drill:

- Tri-Flute Geometry: Improved hole size control and smoother surface finish.

- 3-Land Support: Provides enhanced guidance and stability during drilling.

- Thicker Web Design: Increases core strength for longer tool life and heavy-duty applications.

- High Feed Capability: Withstands more aggressive cutting conditions.

- Solid Carbide Construction: Delivers excellent wear resistance and heat tolerance.

- Versatile Use: Performs exceptionally in both hand drilling and automated systems.

For Best Use On

- Carbon Fibre (CFRP)

- Glass Fibre (GFRP)

- Graphite Composites

- Reinforced Polymers

- Carbon + Aluminium Stacks

- Hybrid Composite Materials

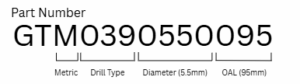

HOW DO OUR PART NUMBERS WORK?