GT-240 Inverted Point Drill

GT-240 Inverted Point Drill

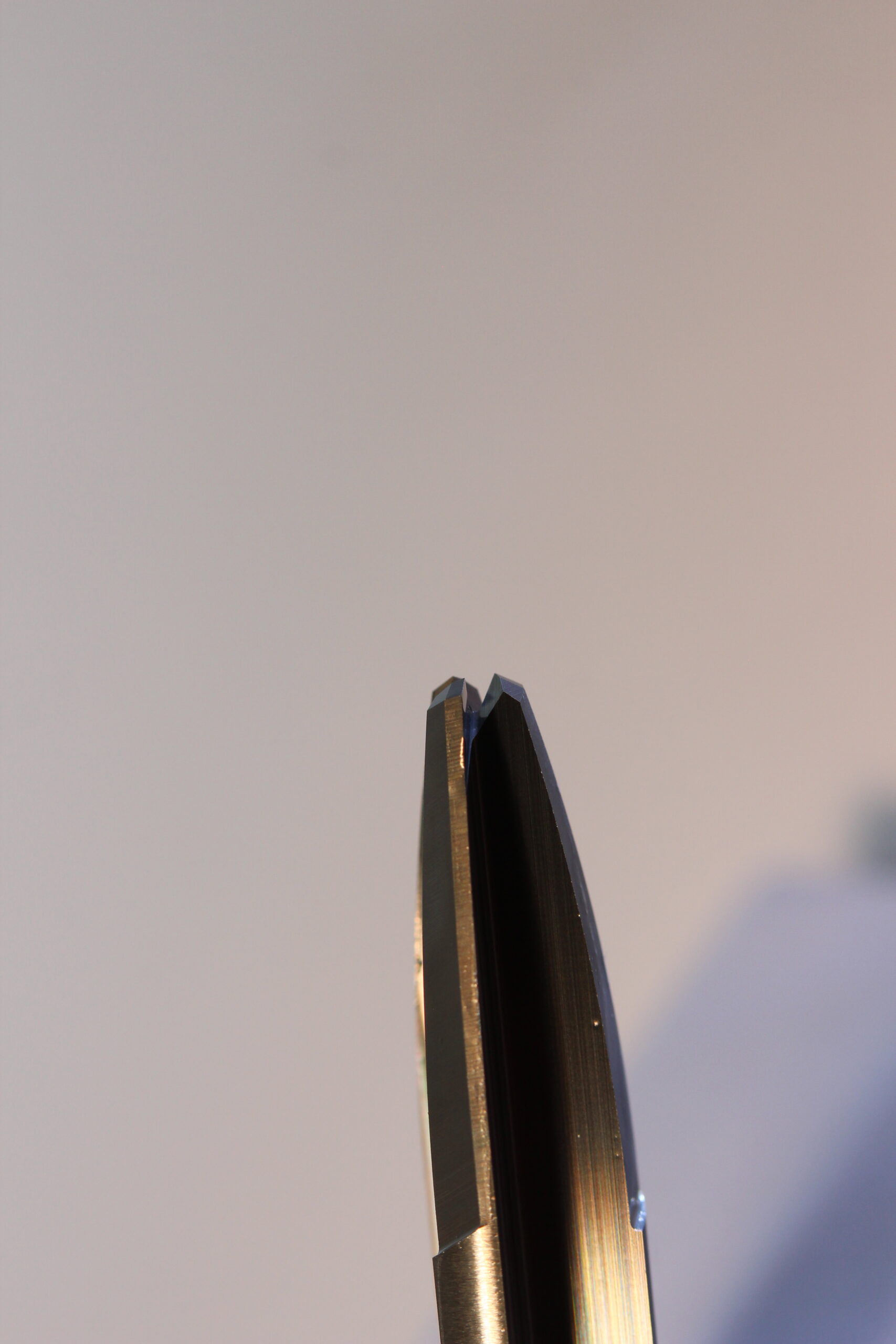

The GT-240 Inverted Point Drill is a solid carbide, high-precision drilling tool engineered for one-shot drilling operations in advanced composite materials. Featuring an inverted point geometry, the GT-240 produces clean, accurately sized holes while minimizing delamination and fibre breakout, even in the most challenging layered composites.

Its unique trepanning cutting action reduces axial force during penetration, making it ideal for CNC and automated feed-controlled machines where precision and repeatability are critical.

Key Benefits:

- One-shot drilling to final hole size without pre-drilling or reaming

- Inverted point geometry reduces delamination and surface damage

- Trepanning cutting action lowers axial thrust and material distortion

- Made from sub-micron solid carbide for extreme wear resistance

- Withstands high cutting temperatures and abrasive materials

- Ideal for automated, feed-controlled composite drilling applications

OPTIMAL FOR USE ON:

- CARBON

- CARBON + ALUMINIUM STACK

- CARBON + TITANIUM STACK

- RIENFORCED THERMOPLASTICS

- GRAPHITE AND LAYERED COMPOSITES

SIZES AVAILABLE:

- From 4mm – 20.0mm +

Intermediate sizes and tolerances upon request

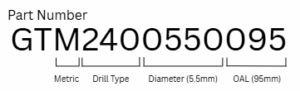

HOW DO OUR PART NUMBERS WORK?